At BRC Food Tech, we specialize in delivering high-performance packaging solutions as part of our comprehensive one-stop service. From raw material supply and customized packaging to OEM design, we support every stage of the process. With offices in both Thailand and China, we offer reliable, flexible services, robust logistics support, and tailored solutions to meet the diverse needs of manufacturers and importers worldwide.

The Ultimate Guide to Packaging Bag Structures & Functional Design Requirements (Comprehensive Collection)

1. Retort Pouches

Requirements: For meat, poultry, and other products. Must have high barrier properties, resistance to bone punctures, no bursting/splitting/shrinkage during retort sterilization, and no odor transfer.

Structure:

- Transparent: BOPA/CPP, PET/CPP, PET/BOPA/CPP, BOPA/PVDC/CPP, PET/PVDC/CPP, GL-PET (ceramic-coated)/BOPA/CPP

- Foil-based: PET/AL/CPP, PA/AL/CPP, PET/PA/AL/CPP, PET/AL/PA/CPP

Design Rationale: - PET: Heat-resistant, rigid, printable, high strength.

- PA (Nylon): Heat-resistant, strong, flexible, high barrier, puncture-resistant.

- AL (Aluminum Foil): An optimal barrier and heat-resistant material.

- CPP: Retort-grade, excellent heat-sealability, non-toxic.

- PVDC: Heat-resistant barrier material.

- GL-PET: Excellent barrier, microwave-transparent.

Note: Use transparent bags for standard retort and foil bags for ultra-high-temperature sterilization.

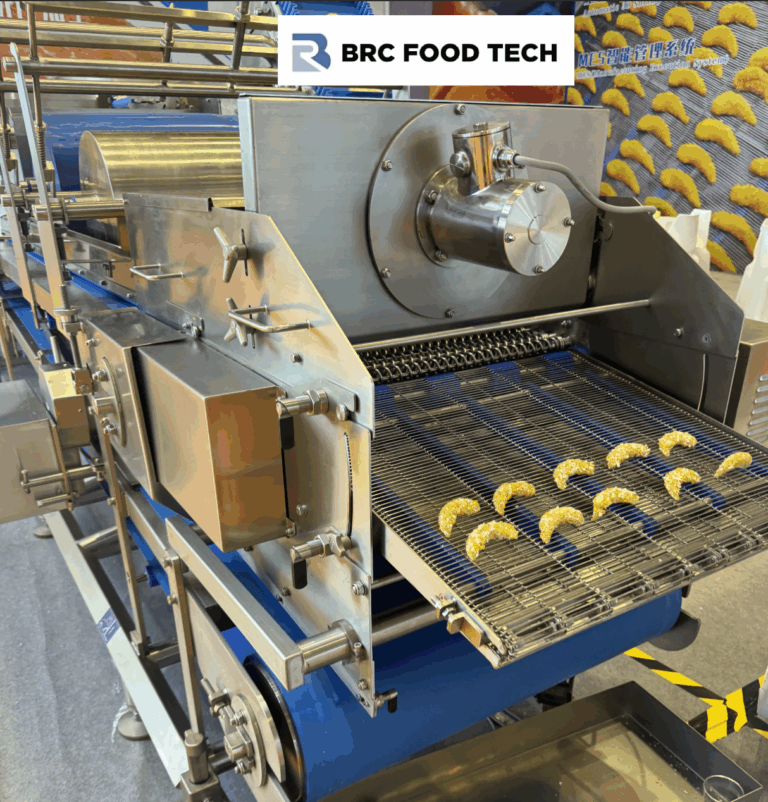

2. Puffed Snack Packaging

Requirements: Oxygen/water vapor/light barrier, grease resistance, aroma retention, stiffness, vibrant print, low cost.

Structure: BOPP/VMCPP

Design Rationale:

- BOPP: Stiff, excellent printability, high gloss.

- VMCPP: High barrier, aroma/moisture protection.

- CPP: Good grease resistance.

3. Fermented Paste Packaging (e.g., Soybean Paste)

Requirements: Odorless, low-temperature sealability, resistance to seal contamination, moderate barrier properties, and cost-effectiveness.

Structure: KPA/S-PE

Design Rationale:

- KPA: Superior barrier, high toughness, strong PE adhesion.

- S-PE (Modified PE): Low sealing temperature, high seal contamination resistance.

4. Biscuit Packaging

Requirements: High barrier, light-blocking, grease-resistant, strong, odorless, and stiff.

Structure: BOPP/EXPE/VMPET/EXPE/S-CPP

Design Rationale:

- BOPP: Rigidity, printability, low cost.

- VMPET: Barrier, O₂/H₂O/light protection.

- S-CPP: Low-temp sealability, grease resistance.

5. Milk Powder Packaging

Requirements: Long shelf life, aroma/oxidation protection, moisture barrier (prevents caking).

Structure: BOPP/VMPET/S-PE

Design Rationale:

- BOPP: Printability, gloss, strength, and cost-effectiveness.

- VMPET: Barrier, light-blocking, toughness (use reinforced thick AL layer).

- S-PE: Contamination-resistant sealing, low-temp sealing.

6. Green Tea Packaging

Requirements: Prevent oxidation (protein, chlorophyll, catechins, vitamin C), discoloration, flavor loss.

Structure: BOPP/AL/PE, BOPP/VMPET/PE, KPET/PE

Design Rationale:

- AL, VMPET, KPET: Excellent O₂/H₂O/odor barriers.

- AL & VMPET: Superior light-blocking.

7. Edible Oil Packaging

Requirements: Oxidation prevention, mechanical/puncture/tear strength, grease resistance, high gloss/transparency.

Structure: PET/AD/PA/AD/PE, PET/PE, PE/EVA/PVDC/EVA/PE, PE/PE

Design Rationale:

- PA, PET, PVDC: Grease-resistant, high barrier.

- PA, PET, PE: High strength. Inner PE: Special grade for contamination resistance.

8. Milk Film Packaging

Requirements: Barrier properties, burst strength, light-blocking, heat-sealability, and cost-effectiveness.

Structure: White PE / White PE / Black PE

Design Rationale: Outer PE: Gloss/strength; Middle PE: Strength; Inner PE: Sealing/barrier/light-blocking.

9. Ground Coffee Packaging

Requirements: Moisture/oxygen barrier, preservation of volatile aromas, resistance to vacuum compaction.

Structure: PET/PE/AL/PE, PA/VMPET/PE

Design Rationale: AL, PA, VMPET: O₂/H₂O barriers; PE: Sealing performance.

10. Chocolate Packaging

Requirements: Barrier, light-blocking, aesthetic print, low-temp sealing.

Structure:

- Plain Chocolate: Varnish/Print/White BOPP/PVDC/Cold-seal adhesive

- Nut Chocolate: Varnish/Print/VMPET/AD/BOPP/PVDC/Cold-seal adhesive

Design Rationale: PVDC/VMPET: High barrier. Cold-seal: Seals at low temps (avoids melting). Nut variants provide an oxygen barrier to prevent oil oxidation.

11. Beverage Packaging

Requirements:

- Acidic (pH <4.5): Pasteurization, moderate barrier.

- Neutral (pH >4.5): Sterilization, high barrier.

Structure: - Acidic: PET/PE (CPP), BOPA/PE (CPP), PET/VMPET/PE

- Neutral: PET/AL/CPP, PET/AL/PA/CPP, PET/AL/PET/CPP, PA/AL/CPP

Design Rationale: Acidic: PET/PA resists pasteurization; acidity extends shelf life. Neutral: AL provides a critical barrier; PET/PA withstands sterilization.

12. Liquid Detergent Stand-up Pouches

Requirements: Strength, impact/puncture resistance, barrier, rigidity (standability), stress-crack resistance, seal integrity.

Structure:

- Body: BOPA/LLDPE; Base: BOPA/LLDPE

- Body: BOPA/Reinforced BOPP/LLDPE; Base: BOPA/LLDPE

- Body: PET/BOPA/Reinforced BOPP/LLDPE; Base: BOPA/LLDPE

Design Rationale: Barrier + rigidity for standability.

Base: Flexible for processing. Reinforced BOPP boosts strength/barrier. PET enhances water resistance.

13. Aseptic Packaging Lids

Requirements: Maintain sterility during packaging/use.

Structure: Coating/AL/Peelable layer/MDPE/LDPE/EVA/Peelable layer/PET

Design Rationale: PET: Peelable sterile protector. AL peel layer: Consumer removal.

MDPE: Rigidity, bonds to AL. LDPE: Cost-effective. EVA: Low-temp sealing (VA ≤7% for food contact).

14. Pesticide Packaging

Requirements: Extreme strength, toughness, impact/drop resistance, seal integrity (critical for toxic contents).

Structure: BOPA/VMPET/S-CPP

Design Rationale:

- BOPA: Puncture resistance, strength, printability.

- VMPET: Strength/barrier (use thick AL coating).

- S-CPP: Sealing/barrier/chemical resistance (terpolymer PP). Alternative: EVOH/PA-based CPP.

15. Heavy-Duty Bags (e.g., Grains, Fertilizers)

Requirements: High strength/toughness, fundamental barrier, and tear resistance.

Structure: PE/Plastic Fabric/PP, PE/Paper/PE/Plastic Fabric/PE, PE/PE

Design Rationale: PE: Sealing/flexibility/drop resistance. Fabric/Paper: Load-bearing strength.